Friends from afar - In October 2018, the laboratory welcomed three graduate and undergraduate students Johannes Hermann, Tobias Bohrer, and Oliver Grill from the Regensburg University of Applied Sciences in Germany. As the first batch of international students who came to Shenzhen Technology University for graduation design research, they conducted a five-week research in the Sino-German beer brewing process control laboratory. In the process, they participated in the student meeting, exchanged and discussed with the undergraduate and graduate students of the school, and visited the high-tech enterprise, Han's Laser.

On October 18, the three foreign students arrived at Shenzhen Shekou Port. Although they have just gone through a journey of up to 24 hours, they were not tired. From the smile, we could see that they were looking forward to this trip to China. On the way to the school, the international students from Germany asked about the situation of Shenzhenand Shenzhen Technology University (under preparation). Two teachers, Wang Yan and Xu Keyan, gave a detailed introduction.

In the first two international courses, it was found that the brewing system had problems such as low degree of automation of temperature control in the saccharification stage and complicated control panels. After studying and thinking about the problems that occurred during the research process, Shen Wenjing of the school had several email communications with Prof. Gerhard Goldmann and Mr. Schrammel, the German OTH professor, to determine the upgrade solution of the brewing equipment. The two systems of PLC + touch screen and LabVIEW combined with the OPC server protocol were used to improve the brewing equipment. At the same time, the graduation project topics and schedules of foreign students were carefully planned around the transformation and upgrading plan. In order to familiarize themselves with the subject, international students also conducted a beer brewing experiment in Mr. Schrammel's laboratory before coming to China.

On October 22, Professor Chen Zhichao, Foreign Affairs Specialist of the Sino-German College of Intelligent Manufacturing, met with the three German students and asked them about their living and studying conditions in the school, determining the issues related to the exchange.

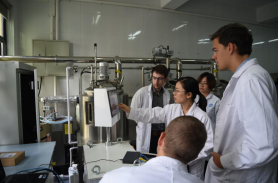

The three German students participated in the debugging of beer brewing equipment and learned the cleaning steps of the beer brewing system under the demonstration and guidance of Mr. He Tiefeng. On the next day, under the guidance of He Tiefeng and the assistance of WangWeiwei, the international students completed the first beer brewing, and practiced the multiple steps of grinding, saccharification, purification, boiling, precipitation, cooling, and fermentation during the beer brewing process. The process and the problems existing in the saccharification process of the original brewing system were deeply understood and learned.

Beer brewing experiment

On October 24, Professor Lyu Qitao, Dean of the Sino-German College of Intelligent Manufacturing, came to the laboratory, welcomed the three German students, and talked with them to learn more about the progress of the research.

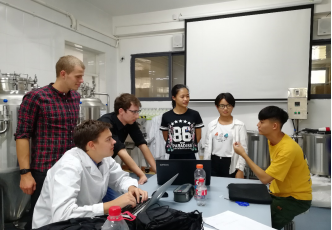

On October 25, Wen Yinchen, Qiu Chunyan, and Yao Pengcheng, three sophomores who had taken the international course Beer Brewing Process Control in the Sino-German College of Intelligent Manufacturing, came to the laboratory to discuss some issues with German students on professional content and experiments, laying the foundation for gradually participating in basic experimental work, and learning the process control knowledge.

|

|

Communication with undergraduates |

Learning brewing system |

In the second week of study for foreign students, Shen Wenjing guided the implementation of the hardware replacement of the equipment modification plan: replacing the solenoid valve with a flow valve to achieve multi-stage flow control of steam heating pipes.

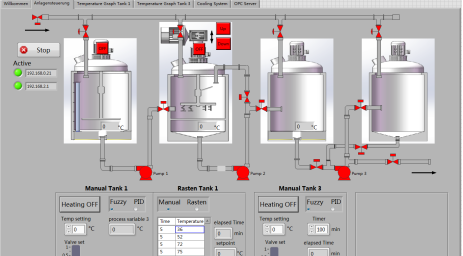

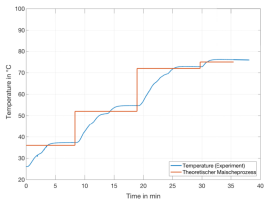

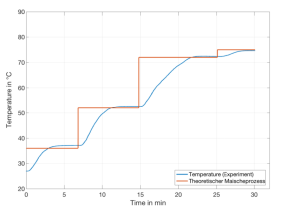

During the experiment, the German students tried to use LabVIEW's OPC server software to establish communication with Siemens S7-200 PLC in the electrical control cabinet of the brewing equipment. In the LabVIEW environment, the PID algorithm and Fuzzy control methodwere introduced to achieve precise and automatic control of the flow valve, so that the saccharification temperature quickly reached the set value without overshooting, and further tested the accessories in the brewing equipment such as the head at the maximum power of the pump, realizing preliminary simulation of the brewing process in Asben Hysys.

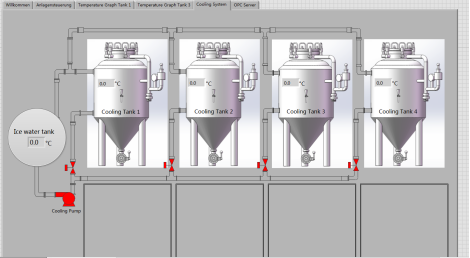

During the third week of study, the international students completed the installation of the OPC server, and used the software to control the pumps and motors of the brewing equipment, and completed the learning task of collecting new and old temperature sensor data. During the course research, teachers and students actively discussed whether to use Chien, Hrones, Reswick and other methods to determine the related issues of PID control's proportional, integral, and differential parameters. However, the steaming of the entire system had serious delay, fuzzy control was adopted finally.

|

|

Wort sugar test |

Manual control after installation of flow valve |

Control interface of brewing equipment in LabVIEW

Control interface of fermentation equipment in LabVIEW

|

|

Temperature step control curve obtained by PID |

Temperature step control curve obtained by Fuzzy control |

In the fourth week, the foreign students proceeded with the research as planned. When fuzzy control is used and fuzzy rules are referenced, it is found that fuzzy control is better than PID control. Therefore, it was decided to embed the Fuzzy algorithm into the LabVIEW control interface, which finally realized the control of the brewing equipment and accurate temperature monitoring. In addition, inspired by college teachers, the international students also installed NI Data Dashboards on their mobile phones, which can directly control and monitor brewing equipment.

Control interface of brewing system on NI Data Dashboards app

Remote video presentation with Prof. Goldmann, Mr. Schrammel on research progress

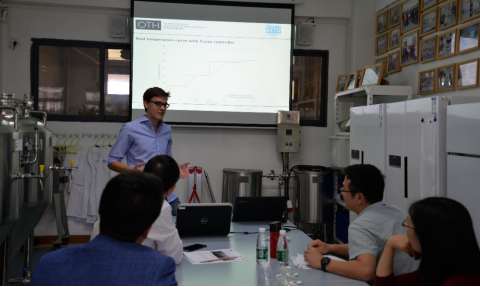

During the last week of study, the teachers and students summarized the problems and planned the follow-up work. On November 22, the three foreign students gave a graduation design presentation in the Sino-German beer brewing process control laboratory of Shenzhen Technology University in the Experiment Building, and introduced their research results for the past five weeks and follow-up plan respectively.

Tobias Bohrer's topic is to use fuzzy logic in LabVIEW to integrate and optimize the temperature controller of the brewery. Tobias Bohrer mainly introduced the quality of the existing controller in his representation, established a simulation model of the saccharification tank in LabVIEW, and calculated the appropriate controller parameters. After that, he introduced the simulation and optimization of the PID and fuzzy control of the simulation model, and realized the optimization of the actual system, including the comparison between simulation and reality. He said that if LabVIEW could be flexibly used to control the temperature during the beer brewing process, the beer brewing would also be more efficient.

Tobias Bohrer 's representation

Johannes Herrmann's project is to use Yang's Hysys software to simulate a beer factory. The presentation mainly includes "creating a single process and component simulation model (Aspen Hysys)", "simulation of a single process and the entire brewing process (Aspen Hysys)", and "collecting parameters of the actual system, optimizing / determining brewing process value". At the same time, he also prepared sample files for student education, which greatly helped the development of the school laboratory.

Johannes Herrmann's presentation

Oliver Grill's thesis topic integrated and parameterized programmable logic controllers in LabVIEW with OPC. He outlined the programming steps for this controller. The creation of the program mainly included reading operation parameters, visualization of measurement data, backing up data in csv format, and moving line engineering assistance. At the same time, Oliver Grill prepared sample files for students of Shenzhen Technology University and showed the relevant content of this controller.

Oliver Grill's presentation

The outstanding work results and defense performance of the three international students were unanimously and highly recognized by the judges. In the process of presentation, the teachers who served as judges pointed out some deficiencies in the experimental process and the production of slides, and put forward constructive suggestions for modification. The judges' serious and rigorous academic attitude and research spirit impressed the three German students. The German students said that they had benefited a lot from the research, and would pay more attention to control details, so as to better presenting the research results.

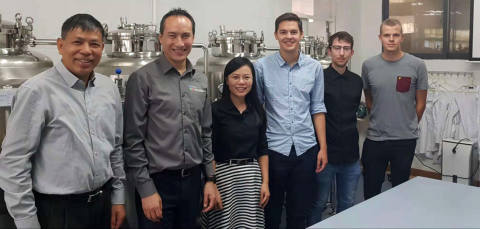

The international students took a photo with all the judges

From left: Professor Wang Hongzhi, Deputy Dean of the Sino-German College of Intelligent Manufacturing, Professor Liu Hongwei, Director of the Academic Affairs Office, Oliver Grill, Tobias Bohrer, Johannes Hermann, Professor Lyu Qitao, Dean of the Sino-German College of Intelligent Manufacturing, Professor Hu Xuejuan, Dean of the Graduate School, and teacher Shen Wenjing of the Sino-German College of Intelligent Manufacturing

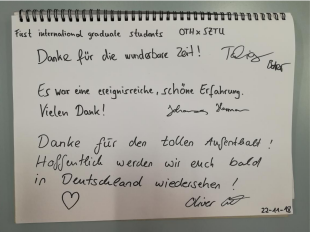

"First international graduate students OTH&SZTU", "Thank you for the wonderful time!-Tobias Bohrer", "This is a very tremendous and beautiful experience. Thank you very much!- Johannes Hermann", "Thank you for the great experience! Hope we can meet you in Deutschland soon! -Oliver Grill"

The three students wrote on the visitors book,"First international graduate students OTH&SZTU", "Thank you for the wonderful time!-Tobias Bohrer", "This is a very tremendous and beautiful experience. Thank you very much!- Johannes Hermann", "Thank you for the great experience! Hope we can meet you in Deutschland soon! -Oliver Grill"

Thanks messages written by the German students after graduation design

This exchange of foreign students created a precedent trial for Shenzhen Technology University to invite German students to perform graduation design in China. During the five-week research, our teachers and three graduate students conducted in-depth and fruitful researches on the three aspects of temperature control accuracy in the saccharification stage, control system integration under the LabVIEW environment, and brewing process simulation. The graduation design is mainly based on equipment transformation and upgrading. It closely integrates academic theoretical research and industrial processes, which reflects the practicability of graduation design propositions, and also provides valuable information for the future exchange activities of Sino-German graduation designs for our students.

After returning to Germany, the international students optimized their graduation designs and continued to write graduation thesis. The picture shows the covers of the undergraduate and graduate theses submitted.