近日,深圳技术大学中德智能制造学院教师申文静与德国雷根斯堡应用技术大学合著的《Analyzation and Optimization of Microbrewery》(酿造系统分析与仿真)一书已由化学工业出版社正式出版发行(ISBN:978-7-122-37153-9),该书由深圳技术大学科研处学术著作出版基金资助。该书籍以全英文的形式,介绍了一种基于LabVIEW平台的啤酒酿造数字化工厂。其以德国啤酒酿造过程为背景,内容包括啤酒酿造系统分析、LabVIEW平台的啤酒酿造数字化工厂的模型,详细介绍了酿造工艺及过程控制的基本知识及新成果并且积极引进德国先进的自动化酿酒控制技术,初步建立了基于LabVIEW平台的啤酒酿造数字化工厂的模型,可为国内的酿酒厂技术人员、管理人员提供有益的参考和借鉴,有助于促进传统酿造行业设备的升级改造。

购书链接:https://www.cip.com.cn/Book/Index/45274

目录

1Introductionandobjective 1

2Generalexplanationofabrewingprocess 4

2.1Ingredients 4

2.1.1Water 4

2.1.2Malt 5

2.1.3Hops 5

2.1.4Yeast 6

2.2Workstepsfortheproductionofbeer 6

2.2.1Grindingofthemalt 7

2.2.2Mashing 7

2.2.3Lautering 7

2.2.4Cookingandadditionofhops 8

2.2.5Hotbreakseparation 8

2.2.6Coolingofthewort 9

2.2.7Pitchingyeast 9

2.2.8Fermentation 9

2.2.9Secondaryfermentationandstoring 9

3Descriptionofthebrewingplant 11

3.1Controllingandmonitoringoftheplant 12

3.2Four-tanksystemfortheproductionofwort 13

3.2.1Mashtank 14

3.2.2Lautertank 16

3.2.3Boilingpot 17

3.2.4Whirlpool 18

3.3Fermentationandstorage 20

3.3.1Plateheatexchanger,yeastcontainerandicewatertank 20

3.3.2Fermentationandstoragetanks 21

3.4Additionalcomponentsofthebrewingplant 22

3.4.1Cleaningofthefermentationtanks 22

3.4.2Grindingofthemalt 23

3.4.3Storageofthemaltandthehops 24

3.4.4Productionofsteam 24

4Collectionofdatafromthemashtank 26

4.1Geometricaldimensions 26

4.2Materialsandwallthicknesses 30

4.3Stirringunit 30

4.4Heattransferfromthesteamtothebrewingwater 31

4.4.1Experimentsforthedistinctionoftheenergysupplybyobservationofthevaporpressure 32

4.4.2CalculationofUSB 33

4.5Totalheattransmissioncoeff?icient 35

4.5.1Experimentsforthemeasurementofthewalltemperatures 37

4.5.2Calculationofho 39

4.5.3Calculationofhi 42

4.5.4Calculationofthetotalheattransmissioncoeff?icient 46

4.6Volumeflowoftapwater 47

4.7Summaryofthevaluesforthemashtank 48

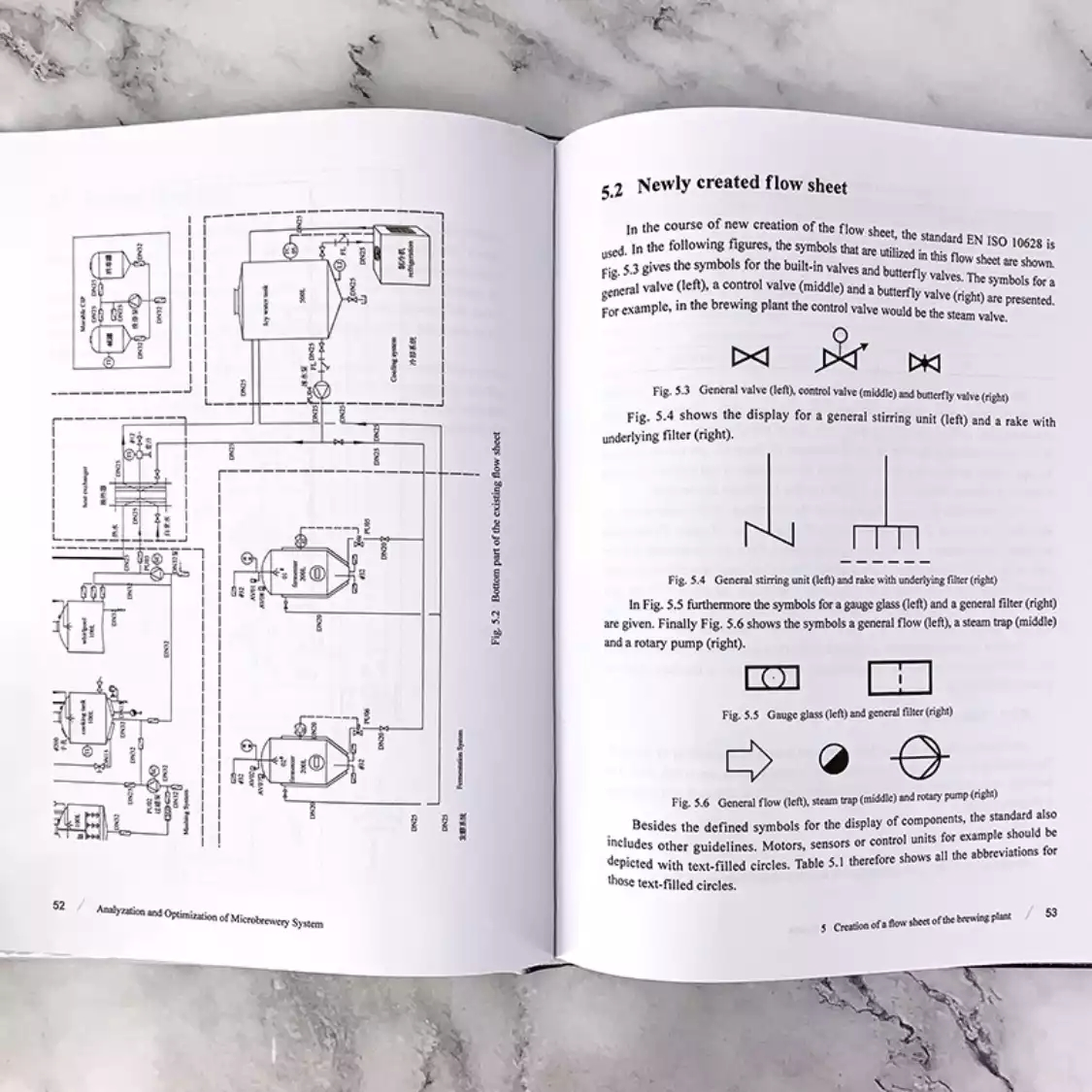

5Creationofaflowsheetofthebrewingplant 49

5.1Existingf?lowsheet 50

5.2Newlycreatedf?lowsheet 53

5.2.1Maltmilling 54

5.2.2Steamproduction 54

5.2.3Productionofwort 58

5.2.4Coolingofthewortandadditionofyeast 59

5.2.5Coolingwatersupply 60

5.2.6Fermentationandstorage 60

6Descriptionofthebrewingprocess 62

6.1Operationoftheplant 62

6.2Cleaningbeforethebrewingprocess 65

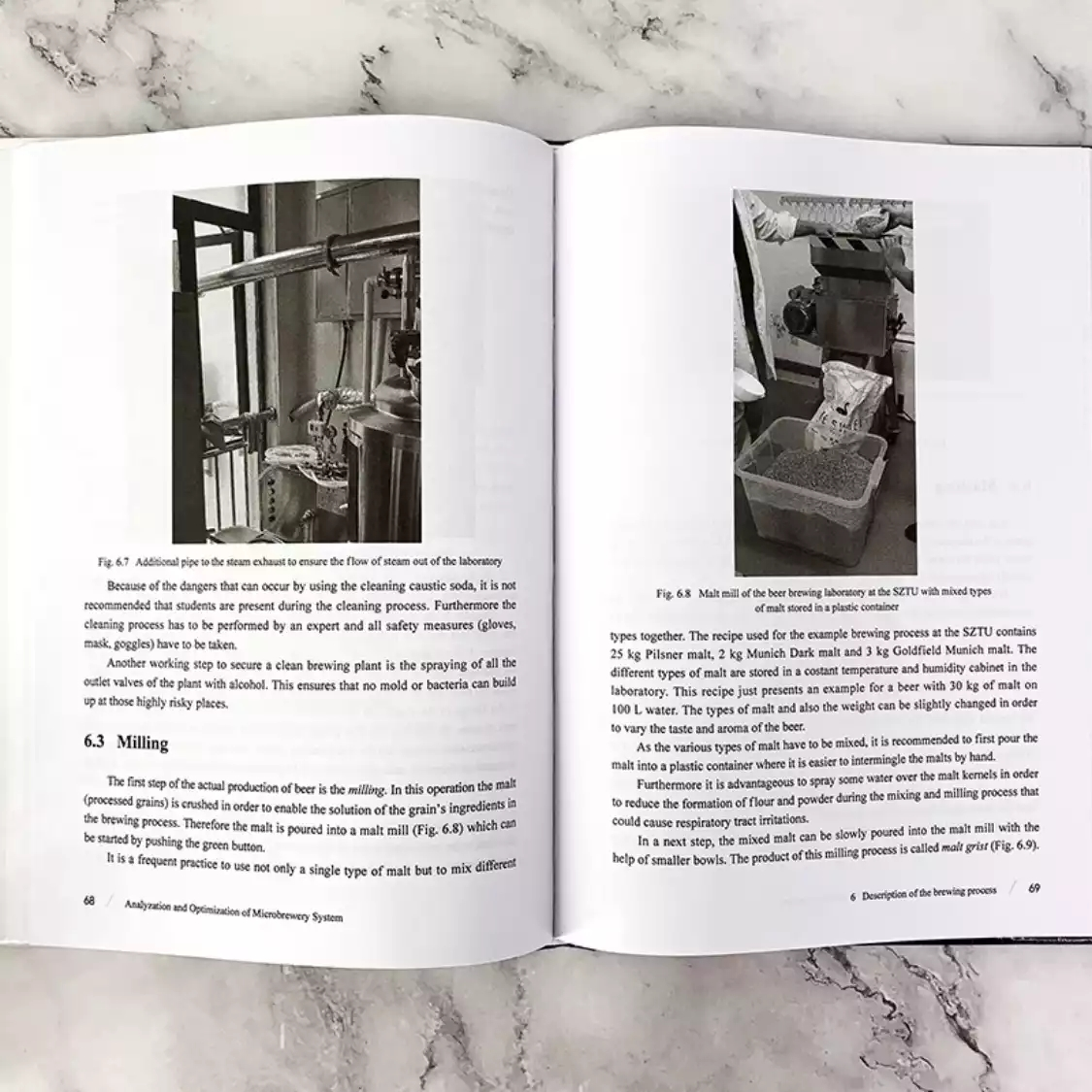

6.3Milling 68

6.4Mashing 70

6.5Lautering 73

6.6Cooking 74

6.7Hotbreakseparation 76

6.8Cooling 76

6.9Pitchingyeast 77

6.10Fermentation 79

6.11Secondaryfermentationandstoringthebeer 80

6.12Cleaningafterthebrewingprocess 81

7Controlofthebrewingplant 84

7.1Fundamentalsofprogrammablelogiccontrollers 84

7.2S7-200SMART 85

7.2.1CPUS7-200SMARTSR40/ST60 85

7.2.2EMAM06 86

7.2.3EMAR04/AR02 86

7.3Switchcabinetwithbasicfunctions 87

7.4Switchcabinetfortemperaturecontrol 89

8Basicsofnetworktechnology 92

8.1IndustrialEthernet 92

8.2OPCFoundation 94

8.3OPCTechnology 95

8.3.1OPCClassic 95

8.3.2OPCUnif?iedArchitecture 97

9ImplementationofaLabVIEWprogram 99

9.1Programinterface 99

9.2OPCServersoftware 100

9.2.1SharedVariableEngine 100

9.2.2DSCmodule 101

9.2.3NIOPCServer 101

9.2.4OPCtags 102

10LabVIEWprogram—brewingplantcontrol 106

10.1Graphicaluserinterface 106

10.2AdvancedFeatures 108

10.2.1DualcontrolofthesystemviaLabVIEWandcontrolpanel 109

10.2.2DataDashboard 111

11Currenttemperaturecontrolsystem 113

11.1Existingcontrollerquality 113

11.2Modif?icationofcontrolvalvesandtemperaturesensor 115

12Simulationofthemashtank’stemperaturecontrol 117

12.1Controllerdesign 117

12.1.1Identif?icationofparameters 117

12.1.2BasicsofPIDcontrolling 120

12.1.3FundamentalsofFuzzycontrol 123

12.1.4PIDcontrollerdesign 128

12.1.5Fuzzycontrollerdesign 130

12.2Build-upofthesimulationinLabVIEW 133

12.2.1Representationofthecontrolledsystem 133

12.2.2Programstructureandfunctionality 134

12.2.3Optimizationofthesimulatedcontrollers 142

13Implementationofthecontrolsystem 146

13.1Operationofthebrewingplant 146

13.2Experimentsontherealsystem 147

13.2.1ExperimentswithPIcontroller 148

13.2.2Experimentswithfuzzycontroller 148

13.3Comparisonbetweensimulationandreality 152

13.4Furtherinvestigations 152

References 155

AppendixA 157

AppendixB 159

Figures 160

Tables 167

审稿:申文静

编辑:李思迪